About Spray Engineering Devices Limited.

Spray Engineering Devices Limited (SED), established in 2004, is a leading engineering company specializing in evaporation, heat exchange, and crystallization technologies. Initially focused on manufacturing spray nozzles, SED has expanded globally, serving over 500 sugar factories in India and 40 countries.

The company operates with an in-house R&D unit and three advanced fabrication plants in Baddi, India. SED has developed and patented several energy-efficient technologies, significantly reducing steam and power consumption in sugar industries. It also offers turnkey project solutions, aiming to optimize resources and enhance productivity.

In addition to revolutionizing water recovery through low-temperature evaporation, SED has introduced a boiler-free Jaggery production unit, promoting sustainable solutions for the sugar and allied sectors.

Buy Spray Engineering Devices Unlisted Shares

| Name | SPRAY ENGINEERING DEVICES LIMITED (Buy unlisted shares) |

| Date of Incorporation | 8 Nov,2004 |

| Industry | Manufacturing |

| Listing Status | unlisted |

| Registered Address | Chandigarh |

| Recent Funding Round | March, 2024 |

| Subsidiaries | SED Engineering and Fabricators Pvltd., Sustainable Environment Development Ltd. |

Timeline

- 1992: Founded by Dr. Vivek Verma in Mohali, focusing on energy and water conservation in the sugar industry.

- 1994-1996: Introduced innovations in sugar manufacturing, improving energy efficiency.

- 2000-2005: Expanded to food processing and wastewater management with advanced technologies.

- 2006: Entered international markets, exporting to Southeast Asia, Latin America, and Africa.

- 2009: Won awards for energy conservation and sugar process optimization innovations.

- 2012-2015: Developed zero-liquid discharge (ZLD) solutions for wastewater management.

- 2018-2020: Gained recognition for sustainability efforts across multiple industries.

- 2023: Continued focus on sustainable and energy-efficient solutions globally

Awards & Achievements

- Excellence Award from The National Sugar Institute (NSI), Kanpur, UP, GOI in 2023.

- National Energy Efficiency Innovation Award from the Bureau of Energy Efficiency (BEE), Ministry of Power, GOI in 2021.

- CSIR Diamond Jubilee Technology Award in 2020.

- CII-National Award for Excellence in Water Management in 2019.

- Amity Global Excellence Award for Sustainable Manufacturing Practices in 2022.

Industry Overview

India’s manufacturing industry, which contributed 16-17% of the GDP pre-pandemic, is poised for rapid growth. Key sectors like automotive, pharmaceuticals, electronics, and consumer durables are driving this expansion, supported by initiatives such as “Make in India” and the Production-Linked Incentive (PLI) schemes. The sector is increasingly adopting digital transformation and automation to enhance efficiency.

In FY23, manufacturing exports hit a record ₹36.8 lakh crore, with a target of ₹82 lakh crore by 2025-26. Leading investment regions like Gujarat, Maharashtra, and Tamil Nadu are strengthening India’s position as a global manufacturing hub, particularly in mobile phone production and the emerging semiconductor sector.

India’s competitive advantages—skilled labor, favorable cost structures, and growing foreign investments—are driving increased production capacity and export growth. Government initiatives like Aatmanirbhar Bharat and Industry 4.0 are fostering innovation, integrating India into global supply chains.

By 2030, India’s manufacturing sector is expected to contribute over ₹40 lakh crore annually to the global economy, with exports playing a major role, aided by technological advancements, government incentives, and an expanding middle class.

Product portfolio

Machinery for Water & Jaggery

Low Temperature Evaporator

Spray Engineering Devices Ltd. (SED) has developed a Low Temperature Evaporator for 100% clean water recovery from wastewater. It uses eco-friendly mechanical vapor compression, requiring no external heat, chemicals, or membranes. With low power costs and full water recycling, it’s ideal for industries like dyeing, distilleries, pharmaceuticals, and textiles.

Machinery for Sugar processing

The Spray Continuous Pan (SCP®)

The Spray Continuous Pan (SCP®) is designed for efficient evaporative crystallization in sugar production, improving yield and quality with lower energy use. It features a multi-chamber vertical vacuum system, suitable for all types of massecuites. Key benefits include low-pressure vapor operation, enhanced sugar recovery (55-60%), and continuous operation with low power consumption. Its modular design ensures faster installation and easy maintenance.

Tubular Falling Film Evaporator

The Tubular Falling Film Evaporator enhances efficiency and reduces steam use in chemical and process industries. Key features include uniform flow distribution, durable stainless steel heating tubes, and high heat transfer. In the sugar industry, it minimizes tube deformation and sugar losses while improving steam economy through multi-effect arrangements.

Plate Type Falling Film Evaporator

The Plate Type Falling Film Evaporator (PTFFE) offers efficient evaporation with high heat transfer (up to 4500 W/m²K) and low-temperature operation, reducing scale formation. Its modular design allows flexible capacity, compact installation, and easy maintenance. Ideal for industries like sugar processing, food, pharmaceuticals, and water treatment.

Mechanical Circulator in Sugar Industry

Spray Engineering Devices Ltd. (SED) developed mechanical circulators for vacuum pans, enhancing sugar production efficiency. They reduce boiling time, improve crystal yield, and lower energy consumption. Key benefits include 30% reduction in strike time, 25-30% increase in pan capacity, and up to 5% higher crystal yield. The six-blade design ensures optimal circulation and easy installation.

Mill electrification

SED’s new planetary mill drive system in sugar production offers a compact and efficient alternative to traditional mills. Key benefits include lower power consumption, precise speed control, reduced noise, and over 90% efficiency. Its design requires minimal maintenance and eliminates the need for external lubrication systems.

Direct Contact Heaters

Direct Contact (DC) Heaters offer efficient heating with a high heat transfer rate and a 0-1°C temperature approach. Key features include a lightweight stainless steel design, compact size, automated controls, and low maintenance. Benefits include up to 5% steam savings, reduced space and pumping requirements, and improved juice clarification. Ideal for heating raw juice and syrup.

Molasses Conditioner

The Molasses Conditioner by SED efficiently dissolves crystals using low-pressure vapors without water, saving steam and power in sugar plants. Key features include a stirrer-free design for trouble-free operation, a compact structure with an inbuilt static mixer, and high heat transfer efficiency. Automated controls ensure smooth operation, while the system offers steam savings (1% on cane) and reduced power consumption. It requires no cleaning and supports flexible installation.

Flash Cigar® Condensate Flashing System

SED’s Flash Cigar® is a multi-chambered horizontal flash vessel designed for efficient heat recovery from multiple condensate streams at varying pressures. Key features include optimal vapor-liquid separation, no control valves for condensate transfer, easy maintenance with manholes and sight glass, and a single pump for centralized condensate removal. Benefits include preventing back pressure, air leakage, and condensate loss while saving energy and steam to enhance efficiency. Ideal for various applications such as for sugar, paper, refineries, chemicals, dairy, and pharmaceuticals.

Sugar Melter

SED’s energy-efficient sugar melter provides consistent brix and temperature while minimizing power, steam, and water usage. Key features include operation under vacuum/low pressure without live steam, a stainless steel vessel capable of handling up to 70-71 Brix, and low steam and power consumption thanks to its in-line planetary drive. Optional automation allows for precise control of brix and temperature.

Services Offered

Project Engineering & Management

SED offers turnkey project solutions, ensuring quality delivery on time and within budget. Our expert team effectively manages time, cost, quality, and resources for superior global services.

Key Services:

- Data collection and computation

- Project monitoring using tools like Primavera

- Scheduling and resource planning

- Erection, commissioning, and automation

- Troubleshooting and performance analysis

SED ensures high-quality project execution across industries such as sugar, food, and energy.

Process and Equipment Design

Key Activities:

- Energy-efficient process design

- Mass-energy balance calculations

- P&IDs and PFDs creation

- Process simulation with SUGARS™

- Thermal design and equipment sizing

The team ensures reliable mechanical design, product layout, and fluid flow optimization for efficient project results.

Equipment Manufacturing

SED’s production division manufactures over 500 tons per day for industries such as water treatment, sugar, refineries, and pharmaceuticals.

Key Features:

- Advanced Equipment: Utilizes CNC plasma cutting, CNC bending, and various welding technologies.

- Extensive Facility: Operates a 12,000 sq. meter production area with a fully equipped machine shop.

- Eco-Friendly Standards: Complies with pollution control regulations and holds ISO 9001:2015 and ISO 14001:2015 certifications.

Their state-of-the-art technology ensures flexible and cost-effective production.

Instrumentation and Automation

SED boosts efficiency in the process and sugar industries through expert automation services.

Key Features:

- Expert Team: Skilled in R&D, software, and project engineering.

- Precision Lab: Ensures instrument accuracy.

- Innovative Tech: Auto cooling systems and SCADA automation.

..

Automation Solutions:

- PLC, HMI, and SCADA systems

- Project engineering and execution

- Instrument testing and maintenance

SED delivers comprehensive solutions for optimal performance.

EPC Solutions

SED provides comprehensive EPC solutions for the process industry, including consultancy, process design, equipment manufacturing, and project management. The key steps involved are client assessment, feasibility study, scope definition, process design (P&IDs and PFDs), simulation and optimization, equipment sizing, project management, execution and commissioning, and performance evaluation. SED serves various industries, such as sugar, refineries, distilleries, food, energy, pharmaceuticals, and wastewater treatment, ensuring efficient and energy-optimized project delivery.

Management

Vivek Verma (chairman cum Managing Director)

.

.

..

..

..

..

Mr. Prateek Verma (Whole-time Director)

..

..

..

,.

..

..

..

Shareholding Pattern

| Particulars | No.of shares | Percentage |

| Promoters | 1,87,96,648 | 82.24% |

| Klondike Investment Ltd | 28,23,348 | 12.35% |

| Others | 12,36,758 | 5.41% |

Spray Engineering Devices Limited Awarded for Innovative Water Recovery Technology at National Energy Efficiency Awards (Dec 21 2021)

Vivek Verma, Managing Director of Spray Engineering Devices Limited (SED) in Mohali, Punjab, received the first prize in the Industries Category for the “Low Temperature Evaporation Technology” at the National Energy Efficiency Innovation Award-2021, organized by the Bureau of Energy Efficiency. This recognition was part of the Azadi ka Amrit Mahotsav celebrations on National Energy Conservation Day at Vigyan Bhawan, New Delhi. SED, established in 1992, focuses on sustainable environmental development and has pioneered innovations in thermal energy recycling, notably the patented Low Temperature Evaporator (LTE®). This technology efficiently recovers up to 99% of clean water from wastewater without external heat sources, promoting Zero Liquid Discharge and significantly reducing carbon footprints. SED operates in over 40 countries and has successfully implemented its solutions in more than 600 sugar factories and 100 water recovery facilities.

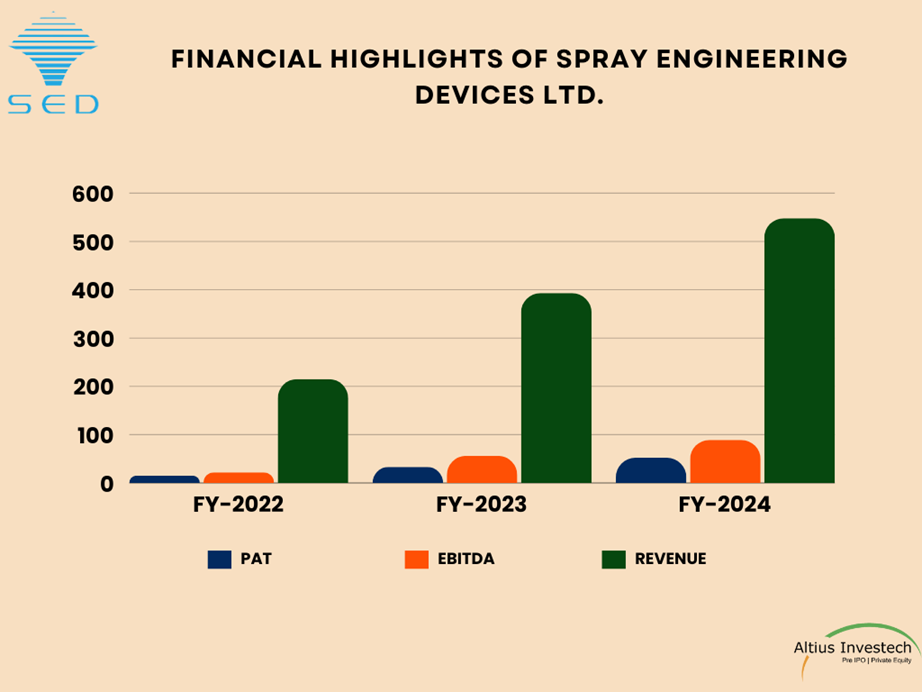

Financial Highlights

₹ in crores

| Particulars | FY 2024 | FY 2023 | Increase% |

| Revenue | 548 | 393 | 39% |

| EBITDA | 89 | 56 | 59% |

| PAT | 52 | 33 | 58% |

| EPS | 23.19 | 14.6 |

Valuation

| Particulars | FY24 |

| Share Price ( September ,2024) | 650 |

| Share Outstanding | 2.25 |

| MCAP | 1463 |

| P/E | 28 |

| P/S | 3 |

Peer Comparison

| Particulars | Spray Engineering Devices Limited | The Anup Engineering Ltd |

| Revenue | 548 | 559 |

| EBITDA | 89 | 136 |

| PAT | 52 | 103 |

| EPS | 23.19 | 52 |

| Share Price (September 2024) | 650 | 2250 |

| MCAP | 1463 | 4493 |

| P/E | 28 | 87 |

| P/S | 3 | 8 |

Key Clients

SWOT Analysis

Strengths:

- Innovative Low Temperature Evaporation Technology with high recovery rates.

- Established global presence in over 40 countries.

- Strong technical expertise and multiple industry awards.

Weaknesses:

- Reliance on specific sectors like sugar and biofuels.

- Limited market awareness outside niche industries.

Opportunities:

- Growing demand for sustainable and efficient water management solutions.

- Potential for expansion in emerging markets.

- Support from government initiatives on energy efficiency.

Threats:

- Intense competition from established and new players.

- Economic downturns affecting capital investment.

- Changes in regulatory landscapes impacting operations

Spray Engineering Devices Ltd. unlisted shares are currently trading at ₹ 650, CLICK HERE to Invest.

Get in touch with us

For any query/ personal assistance feel free to reach out at support@Altiusinvestech.com or call us at +91-8240614850.

To know, more about Unlisted Company. Click here – https://altiusinvestech.com/blog/what-is-listed-and-unlisted-company

To buy unlisted shares Visit – https://altiusinvestech.com/companymain

To know more about How to apply for an IPO? Click- https://altiusinvestech.com/blog/how-to-apply-for-an-ipo/

Visit our website homepage: https://altiusinvestech.com/

Read More